To put the engine under the load condition, carefully engage cutter deck, impeller and various other driven parts. Be cautious and keep your body parts, hands, hair, clothes, and accessories at a distance from all the moving parts. There can be some really severe injuries resulting from rotating parts. If it is necessary, the main adjustment can be done with the engine in a loaded condition.Ĭaution: It has been advised to never operate the engine after removing the covers and guards. Set down the speed controlling carefully to the IDLE position or to the SLOW position, precisely check for an appropriate IDLE or SLOW pace RPM and at that particular point the idle mixture screw need to be adjusted and in the same way as the main mixture screw.

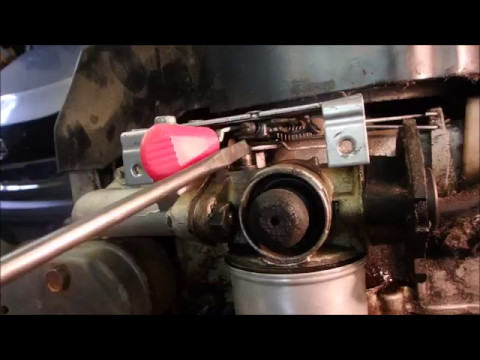

Now to find out best setting point, turn screw to the clockwise direction towards midway between these two positions and that would indicate best setting point adjustment. Repeat the same in reverse direction and now turn the adjusting screw out in counterclockwise direction until the engine reaches a point from where it begins to run in an erratic manner. Once the engine picks up the speed and high or fast speed has been set, it is then advisable to turn on the main mixture adjusting screw to the clockwise slowly-slowly till the point when engine begins to run inconsistent and note down carefully the position of screw at this point of time. Upon starting the engine, initially allow the engine to warm up to a normal working temperature. The adjustments for both the system are pretty much the same however, the drops off point indicate may not be as noticeable. For air adjust system, long needle is used and for fuel adjustments the short ones are used.

Different types have diverse style of idle adjustments the series 1 carburetor comes with two varying styles of adjusting needle for the idle. Note: Some models may have fixed main jet feature characterized by the absence of adjusting screws that gives a clear indication of a fixed jet that requires no adjustment.

After that, slowly back out the screws in a counterclockwise direction to the pre-set position. Turn screws adjusting both idle and main mixture in (clockwise) finger tight, however over tightening the screws may partially or entirely damage the tapered portion of the needle.

0 kommentar(er)

0 kommentar(er)